Sponsored Content

How freshwater collagen is moving anti-aging into the circular beauty era...

24 Feb 2023

Circular beauty is reshaping the nutricosmetics industry. Today, products need to do more than just provide beauty from within; they also need to be good for people and the planet.

The demand for sustainable beauty is a threat to manufacturers of traditional collagen anti-aging products made from cows, pigs, or marine fish—all of which have weak environmental credentials. Willows Ingredients is helping brands nullify the threat with sustainable, eco-friendly collagen from freshwater fish.

Delivering a sustainable, traceable collagen that meets demands to protect the seas

The sustainability of marine ecosystems is now a major concern for many people. With consumers rethinking their buying habits in light of worries about their impact on the seas, manufacturers that use collagen from marine sources face a potential threat to their businesses. Willows Ingredients is helping manufacturers to eliminate the threat by providing a fully traceable collagen from freshwater fish.

Concerns about the impact we are having on the marine environment have been mounting for years.

In 2018, a survey of 18,909 seafood consumers in 22 countries found 83% of people think we need to do more to protect the seas for future generations.1 A separate survey conducted the following year revealed similar proportions of consumers are worried about contaminants, ocean pollution and the extinction of wild fish species.2

The debate reached a wider audience in 2021 with the release of the widely watched documentary, Seaspiracy. It is too early to tell what lasting impact the documentary will have on attitudes to the consumption of sea fish but there is limited, early evidence that it could drive behavioural change.3, 4

Growing focus on the sustainability and traceability of the marine supply chain are in line with wider changes in the priorities of consumers. More than half of consumers say sustainability considerations influence their eating habits.5 Those priorities are reflected in growth in sales of sustainable goods, which a European Union poll found is accelerating faster in the food industry than in other sectors.6

The nutrition industry is exposed to the same forces. Sustainability was influencing 69% of younger dietary supplement consumers even before the increased focus on environmental issues seen over the past few years.7 Most Millenials expressed a willingness to pay more for sustainable products.

Those data paint a clear picture of what consumers want. Yet, recognising the market demand and commercial opportunity is only part of the challenge. Manufacturers also need access to ingredients that have the sustainability and traceability credentials expected by consumers.

Creating a controlled supply chain

Collagen, an ingredient used in joint and skin health products, has posed challenges to companies that want to develop sustainable, traceable supplements. The protein is found in the bones and skin of animals and fish. Some collagen supplements use bovine or porcine sources of the protein while others extract the ingredient from marine life such as cod and pollock.

Marine collagen is preferred by some consumers, for reasons such as dietary considerations, leading to forecasts that it will be the fastest-growing source of the protein.8,9 However, rising demand for the protein threatens to exacerbate growing global concerns about our impact on the seas and drive consumers to seek alternative sources or turn away from collagen altogether. Working with partner, Vinh Hoan Corporation, Willows is helping manufacturers of collagen products to respond to the situation.

Vinh Hoan has developed an alternative to marine collagen—called Vinh Wellness Collagen—that has the characteristics needed to succeed with environmentally conscious consumers. Rather than extract collagen from sea creatures, Vinh Hoan farms a species of freshwater, tropical fish called Pangasius hypophthalmus.

The approach eliminates the concerns with sourcing collagen from fish. While taking collagen from marine fish adds to the burden we place on the seas, the closed-chain aquaculture practiced by Vinh Hoan is cut off from those pressured ecosystems. Vinh Hoan breeds, farms and processes fish itself.

The model, and the proximity of the ponds and plants, enables Vinh Hoan to process fish into collagen within 24 hours.

As Vinh Hoan is in control of the whole system, it can trace a collagen product back to the start of the process. Vinh Hoan knows where and when fish used to make a specific collagen product were harvested.

That level of traceability sets Vinh Hoan apart from producers of marine collagen, which can typically only track their products back to the processing plant and even to fish farm. All the critical details from before that point in the supply chain, including which species were used to make the collagen, are unknown. The total lack of information makes it impossible to address consumer concerns about whether the fish were caught using unsustainable fishing methods or were tainted with plastics or heavy metals.

The benefits of the level of control Vinh Hoan has over the aquaculture system extend beyond satisfying consumer demands for sustainable and traceable products. Vinh Hoan’s control also enables it to deliver a collagen product that is more consistent than many sources of marine collagen. Marine collagen is often made from blends of different species of fish, each of which has its own amino acid profile. As the blend is always changing, the chemical composition of the collagen varies from batch to batch and year to year.

Vinh Wellness, in contrast, is only produced by a single source of fish skin. The single-source approach enables Vinh Wellness to keep delivering the same unique amino acid profile again and again to ensure consumers receive the same benefits and effects every time they use a collagen product. Vinh Wellness collagen is characterized by high concentrations of glycine, proline, and hydroxyproline, which represent 50% of the total amino acids. Unlike collagen from marine sources, the Vinh Wellness product is low in sodium.

Validating the operation

Vinh Hoan’s operation, which can make 1,000 tons of collagen peptides a year, has received a wide range of accreditations validating its commitment to quality. The aquaculture facilities are certified by the Aquaculture Stewardship Council (ASC), comply with Global Good Aquaculture Practices and adhere to a range of other standards including ISO requirements on quality and environmental management.

With Vinh Hoan’s modern processing plant meeting European standards, the company is equipped to serve Western markets with a pure, pharmaceutical-grade collagen peptide. The availability of the collagen peptide creates opportunities for manufacturers of health and wellness products, nutraceuticals and cosmeceuticals who want to ensure the ingredients they source are produced safely, sustainably, and ethically.

Manufacturers that seize the opportunity stand to address consumer demands for products that are equally good for the planet and their own wellbeing, thereby positioning themselves to support the ongoing shift toward sustainability and traceability.

References

- Seafood consumers want less pollution and more fish in the sea.

- US seafood consumers conflicted over sustainable options. PR Newswire (2019).

- Fletcher, H. Nearly half the people who watch Netflix’s Seaspiracy consider giving up fish. Metro.co.uk (2021).

- Bradley, S. Can Netflix’s Seaspiracy really shock people into not eating fish? WIRED UK (2021).

- Most EU consumers open to eat more sustainably but face hurdles, new survey shows.

- The European Union market for sustainable products.

Related news

Benefits of using natural antioxidants in food

20 Nov 2025

The dietary habits of individuals are undergoing a transformation, with consumers increasingly seeking new, healthier, and higher-quality formulas. This shift signifies a growing awareness of food ingredients, including preservatives, additives, a...

Read more

Oat Barista: Innovation for game-changing beverages

20 Nov 2025

Oat Barista is a clean label, sustainable, and innovative drink base specifically designed to create the perfect foam in one single ingredient.

Read more

The Umami Renaissance: Clean Label & Cost Control with Ready-to-Use Fungal Bases

19 Nov 2025

Consumers demand authentic, rich flavor (Umami) and simple labels. The fungal protein market is growing at a 5.6% CAGR, offering manufacturers the solution: heat-stable, natural bases that eliminate prep costs and supply risks associated with raw wild ...

Read more

Azelis brings a taste of global street food innovation to Food Ingredients Europe 2025

18 Nov 2025

Azelis, the reference innovation service provider in the speciality chemicals and food ingredients industry, will showcase its latest Food & Nutrition innovations at Food Ingredients Europe (FiE) 2025, taking place from 2 to 4 December at Paris Expo Po...

Read more

PharmaLinea acquired by ANJAC Health & Beauty Group

18 Nov 2025

Ljubljana, 12.11. 2025 PharmaLinea, a leading provider of clinically supported private label food supplements has announced its acquisition by ANJAC Health & Beauty, a French industrial group that now comprises 17 complementary companies with R&D an...

Read more

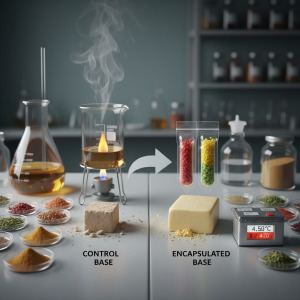

The Heat Test: How Encapsulation and Bases are Ending the Multi-Billion Dollar Flavor Fade

18 Nov 2025

Flavor degradation during heat processing is a major financial risk in food manufacturing. In 2025, R&D is shifting to advanced encapsulation and heat-stable bases to protect volatile flavor compounds and ensure final product consistency.

Read more

Use Case Spotlight: Versatile Bases Solve Key Challenges in Ready Meals, Sauces, and Cheese

17 Nov 2025

Ready-to-use bases are the manufacturing solution for the $425 Billion RTE market. Our versatile ingredients solve core issues in three top categories: taste, clean-label compliance, and complex texture stability.

Read more

Hilmar Cheese & Whey Protein Awarded Medals

17 Nov 2025

Hilmar Cheese Company, Inc. was awarded top honors at the CheeseCon banquet celebrating the United States Championship Cheese Contest® on April 17, 2025.

Read more

Hilmar Cuts the Ribbon at New Dodge City Facility

17 Nov 2025

Hilmar Cheese Company, Inc., one of the world’s largest cheese manufacturers and a global supplier of high-quality whey ingredients was joined by Kansas Governor Kelly, U.S. Senator Moran and other federal, state and local officials to officially mark ...

Read more

Data Insight: Clean-Label Adoption Drives US$425 Billion Market, Prioritizing Simplicity and Natural Flavors

14 Nov 2025

The Clean Label Products market is projected to grow from US$425.32 billion in 2025 to over US$712 billion by 2034, driven by consumers prioritizing recognizability, minimal processing, and natural ingredient replacement.

Read more